Sheet Metal Fastening Methods

Fasteners Hold A Firm Fix In Thin Sheet Metal

Methods For Mechanical Joining Of Aluminum Parts

How To Join Sheet Metal Parts Sheet Metal Joining Techniques

Methods For Mechanical Joining Of Aluminum Parts

Clinching Welding Machines And Consumables Www Weldnbraze Com

The Power Of Sheet Metal Design

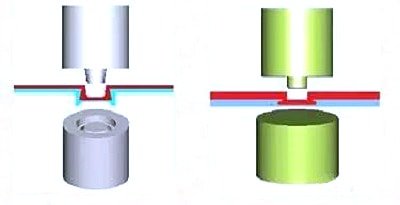

Welding methods have some constraints when joining fasteners to sheet metal.

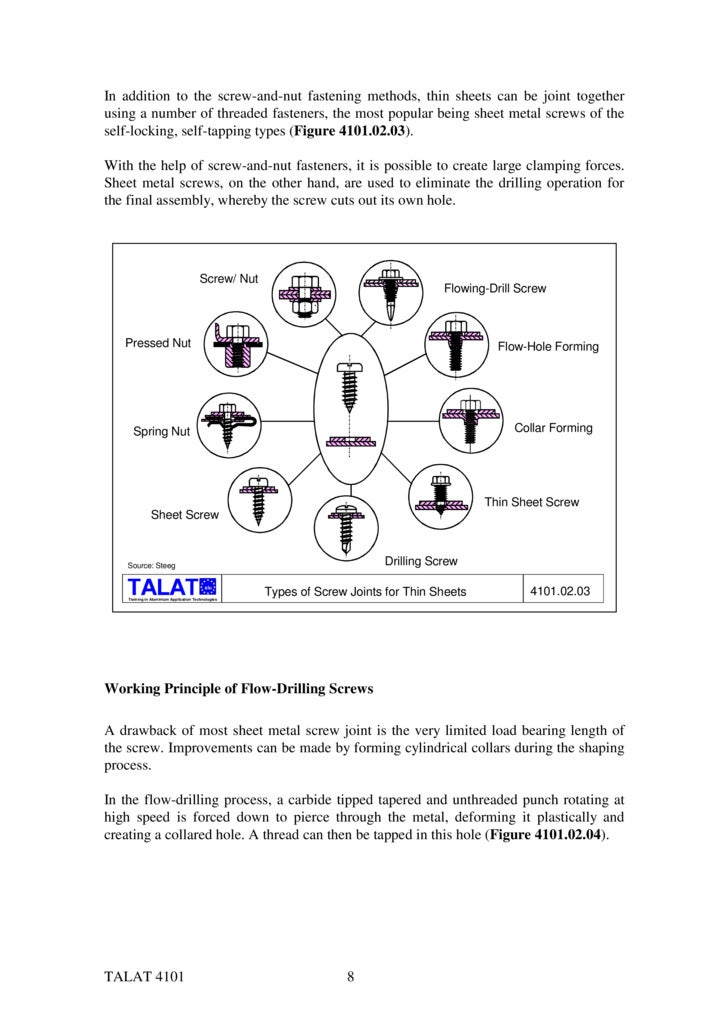

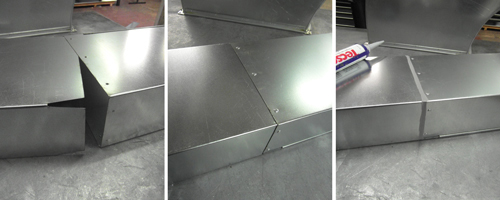

Sheet metal fastening methods. Since they become integral parts of the assembly during fabrication, they do not loosen or fall out and never have to be handled again. Both need holes through the sheet metal but bolts use a nut on the backside to tighten the joint. This process does not require additional hardware and can be done on sheet metal bending machines.

They can be installed during fabrication to eliminate loose hardware during final assembly. Which is best depends on the material, its thickness and the application requirements. Secure fastening by any other method.

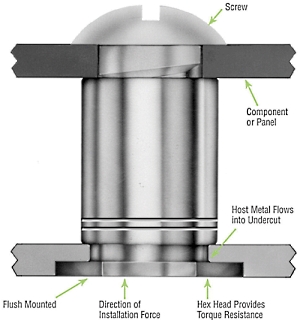

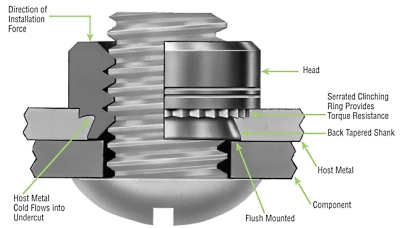

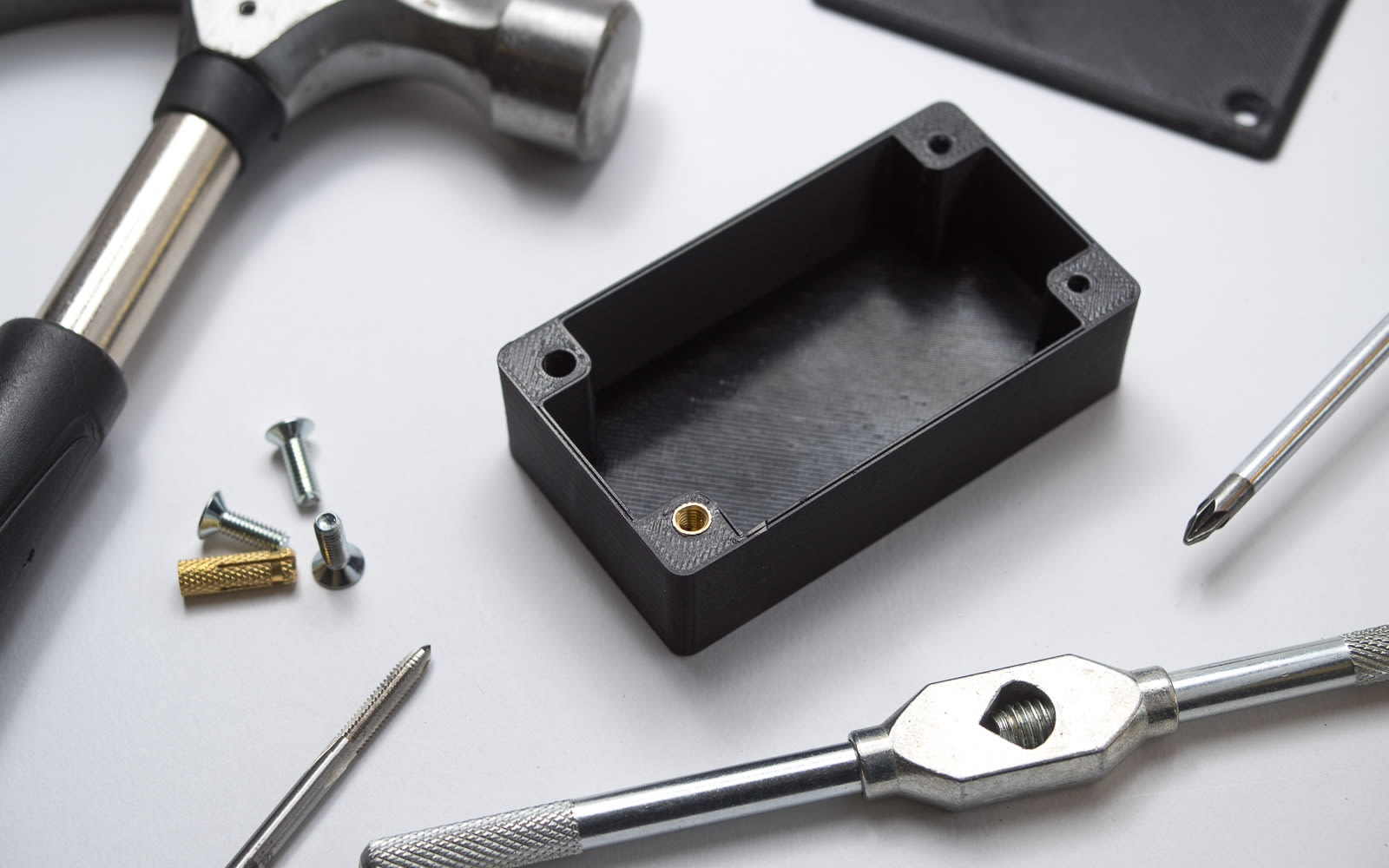

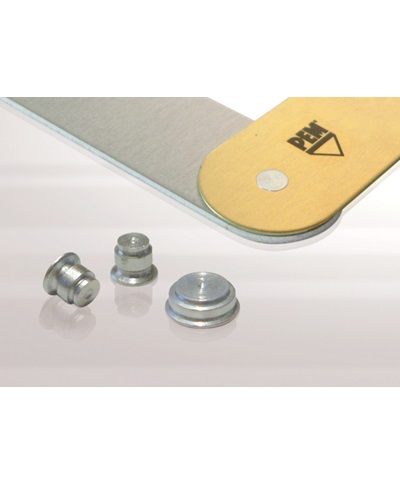

Fasteners and assembly products from STANLEY ® Engineered Fastening include threaded inserts for plastics, blind rivets and tools, self-locking thread systems, and torque tool solutions. The self-clinching nut is a threaded fastener with an annular recess in its shank. Unlike other methods, self-clinching fasteners give permanent, reliable, and reusable load-bearing threads in thin metal sheets.

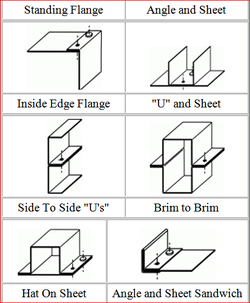

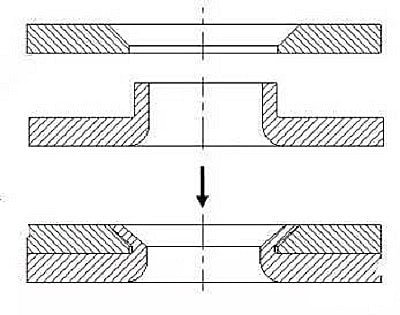

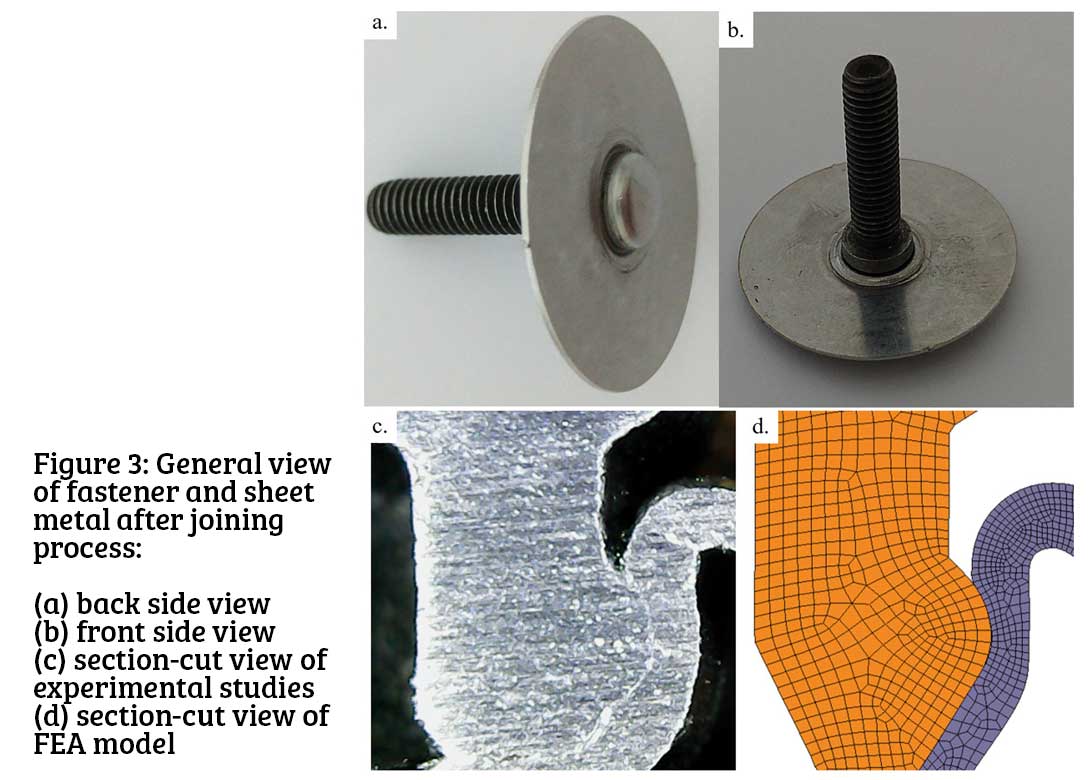

Folding or bending tabs is an economical way for making permanent sheet metal joints. Whether residential or commercial, HVAC and sheet metal applications require an array of highly-specific fastener and assembly solutions to ensure optimal performance and extended product life. Currently, two main methods are used for the joining of a fastener to sheet metal – conventional welding and self-clinching fasteners (SCF).

Even if the sheet is thick enough to sustain tapping, it may actually be more economical to use self-clinching fasteners with gaugeable threads. Reusable Methods of Joining Sheet Metal Bolts and screws top this list. Screws on the other hand hold a joint together by griping a thread cut into the metal.

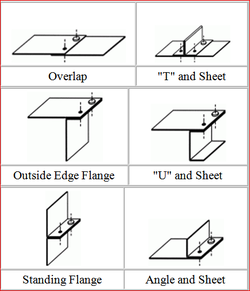

Folding and adding bending tabs is one of the easiest and most economical way of making moderately strong joints in sheet-metal parts that will permanently or semi-permanently attach to one. Appliance engineers have several options for joining sheet metal, including screws, rivets, welding, bonding, clinching and folding. Most engineers rely heavily on mechanical fasteners.

From Snap Fits To Adhesives A Comprehensive Guide To Mechanical Fastener Options Fictiv

Pin On Metal

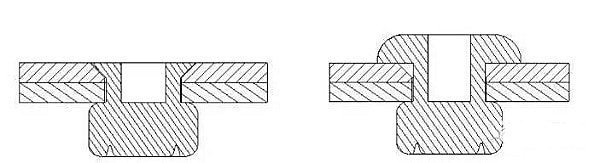

English Clinching Technology Joining Sheet Metal Without Welding Nor Fasteners Rivclinch Youtube

6 Types Of Sheet Metal Joining Techniques Machinemfg

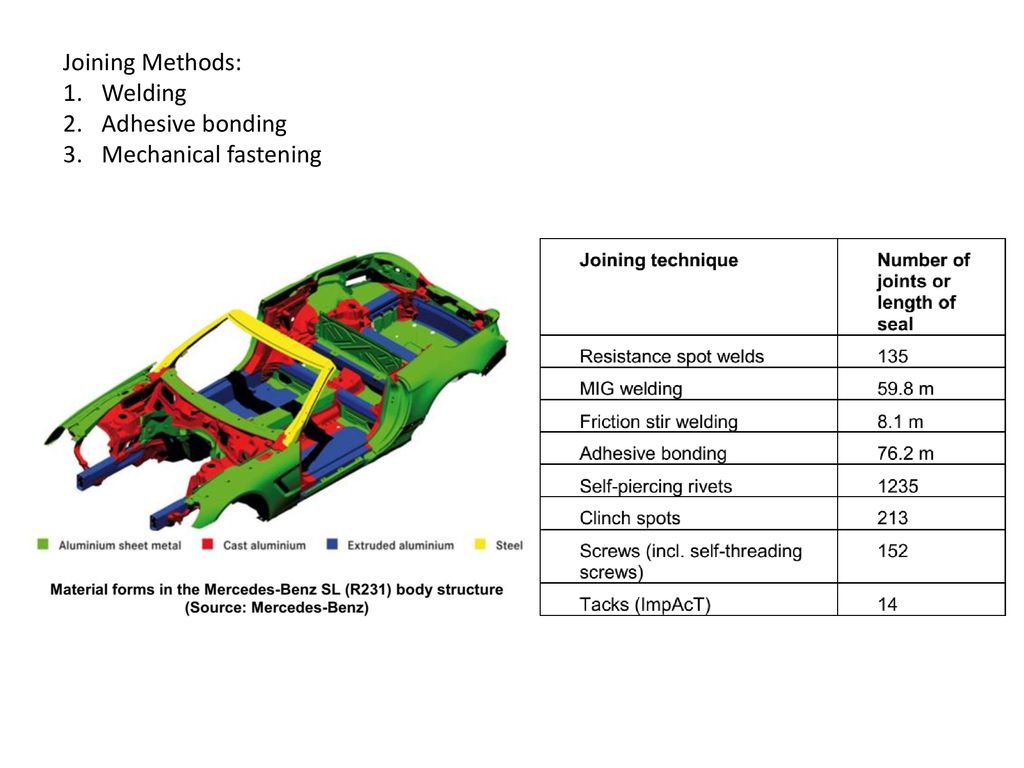

Joining Methods Welding Adhesive Bonding Mechanical Fastening Ppt Download

An Innovative Fastening Approach For Thin Sheet Metals And Modelling By Finite Element Method Fastener Fixing Magazine

Solid Shank Rivet Aircraft Structural Fasteners Aircraft Systems

Www Smacna Org Docs Default Source Market Sector Architectural Manual Pp Pdf

How To Use Self Clinching Fasteners On Stainless Steel Machine Design

Overview Of Techniques For Joining Dissimilar Materials

Forming On The Modern Punch Press Sheet Metal Fabrication S Swiss Army Knife Mate Precision Technologies

6 Types Of Sheet Metal Joining Techniques Machinemfg

Think You Re Cut Out For Doing Sheet Metal Role Take This Quiz Holdentkgi450 Over Blog Com

Pin On Construction Assembly Methods

An Innovative Fastening Approach For Thin Sheet Metals And Modelling By Finite Element Method Fastener Fixing Magazine

Repairability Of Sheet Metal Structures Part Four

6 Types Of Sheet Metal Joining Techniques Machinemfg

Structure Magazine Expansion Bolts For Hollow Structural Steel Sections

Skill Builder Know Your Rivets Workshop Make

Methods For Fastening Sheet Metal Without Fasteners Sheet Metal Sheet Metal Fabrication Metal Working

And Stainless Steel Fastenright Ltd

7 Best Joint Strength Images Sheet Metal Metal Working Metal Design

Testing Of Bolts Screws And Studs

Galling Wikipedia

From Snap Fits To Adhesives A Comprehensive Guide To Mechanical Fastener Options Fictiv

Fastening Technique Replaces Traditional Assembly Methods Designnews Com

How To Join Sheet Metal Parts Sheet Metal Joining Techniques

1

Methods For Fastening Sheet Metal Without Fasteners Machine Design

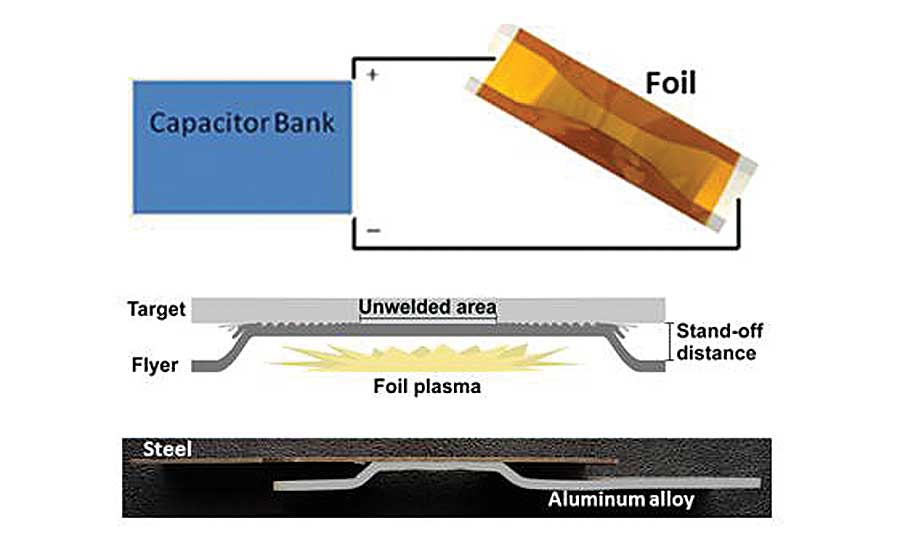

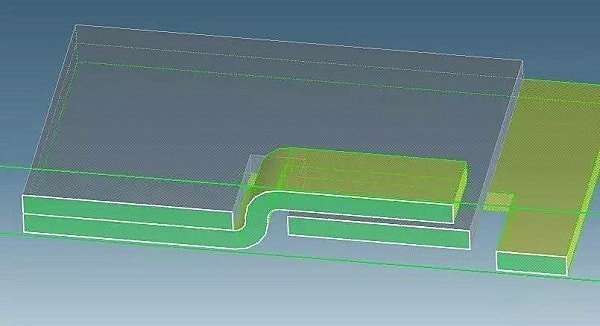

New Techniques For Joining Steel And Aluminum 17 04 11 Assembly Magazine

How To Join Sheet Metal Parts Sheet Metal Joining Techniques

Clinch Fasteners For Sheet Metal Inserts For Plastic And Relevant Products Psm

Methods For Mechanical Joining Of Aluminum Parts

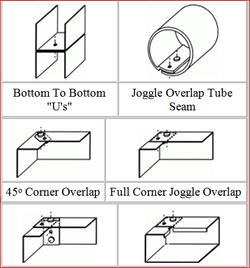

Fabrication Of Edges Joints Seams And Notches Sheet Metal Work Sheet Metal Sheet Metal Fabrication

Value Add Operations For Sheet Metal Components

6 Types Of Sheet Metal Joining Techniques Machinemfg

Techniques For Joining Sheet Metal 13 06 03 Assembly Magazine

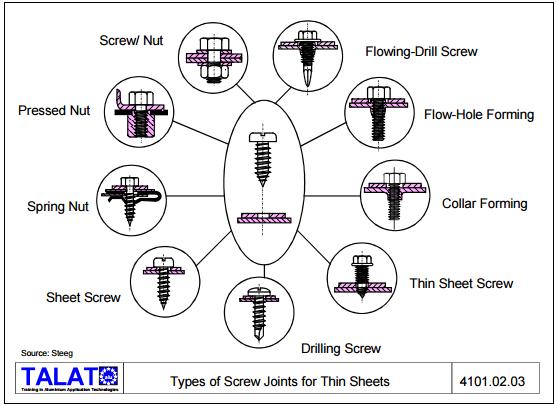

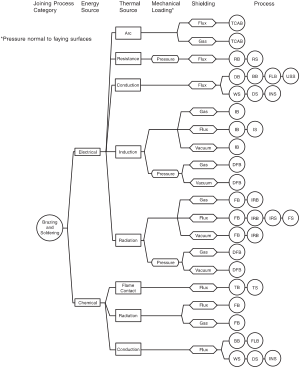

Talat Lecture 4101 Definition And Classification Of Mechanical Faste

Q Tbn 3aand9gct9o C6fosex1lbe5z0f8mj9yun9wreclrm5flo1ecpj3bdwtoy Usqp Cau

The Key Differences Between Flush Head Fasteners And Concealed Head Fasteners Protocase Blog

Brazing Wikipedia

Www Smacna Org Docs Default Source Market Sector Architectural Manual Pp Pdf

Www Smacna Org Docs Default Source Market Sector Architectural Manual Pp Pdf

How To Join Sheet Metal Parts Sheet Metal Joining Techniques

A New Joining By Forming Process To Produce Lap Joints In Metal Sheets Sciencedirect

Ares D O O Services

7 Ways To Improve Sheet Metal Parts

Clinching Welding Machines And Consumables Www Weldnbraze Com

Working Principles 4 Metal Sheet Design Sheet Metal Metal Shaping

Permanent Vs Reusable Joints For Sheet Metal Part Assembly Wiley Metal

Www Fluidsealing Com Publication Downloads Fsa gasket handbook june 17 Pdf

Thermal Drilling Processing On Sheet Metals A Review Sciencedirect

Rectangular Ductwork Joining Methods Rectangular Ducting Help Ducting Supplies

Techniques For Joining Sheet Metal 13 06 03 Assembly Magazine

Sheet Metal Forming Processes And Equipment Machinemfg

Pin On Blacha

Image Result For Sheet Metal Joining Methods Sheet Metal Fabrication Sheet Metal Work Sheet Metal

Fasteners Hold A Firm Fix In Thin Sheet Metal

Methods For Mechanical Joining Of Aluminum Parts

Types Of Metal Fabrication Processes Considerations For Choosing A Fabricator

How To Join Sheet Metal Parts Sheet Metal Joining Techniques

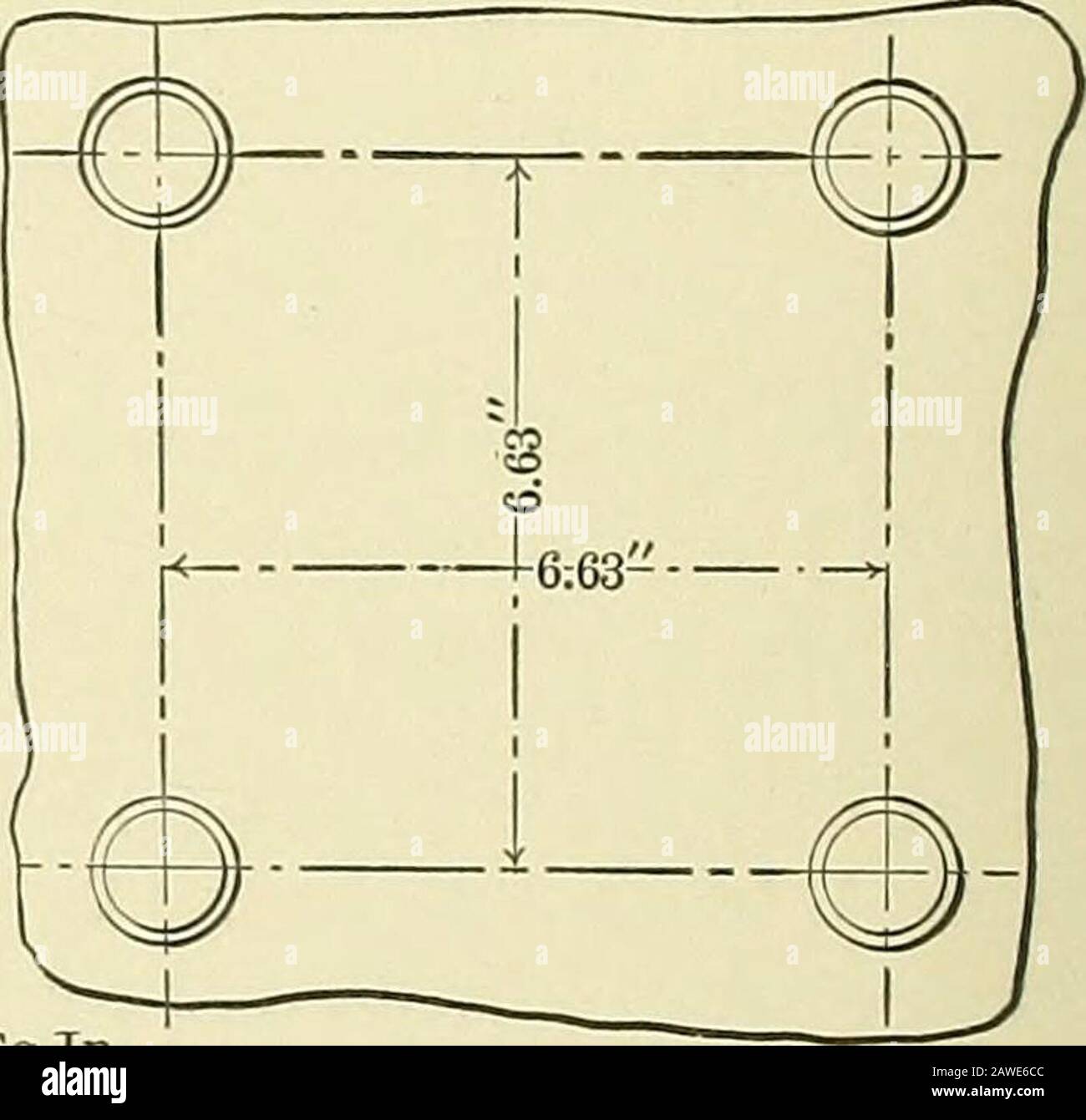

Laying Out For Boiler Makers And Sheet Metal Workers A Practical Treatise On The Layout Of Boilers Stacks Tanks Pipes Elbows And Miscellaneous Sheet Metal Work Area 1 28 Sq In Imc Diam Fig

Assembly By Clipping For The Automotive Industry Araymond

Overview Of Techniques For Joining Dissimilar Materials

6 Types Of Sheet Metal Joining Techniques Machinemfg

Extruded Hole An Overview Sciencedirect Topics

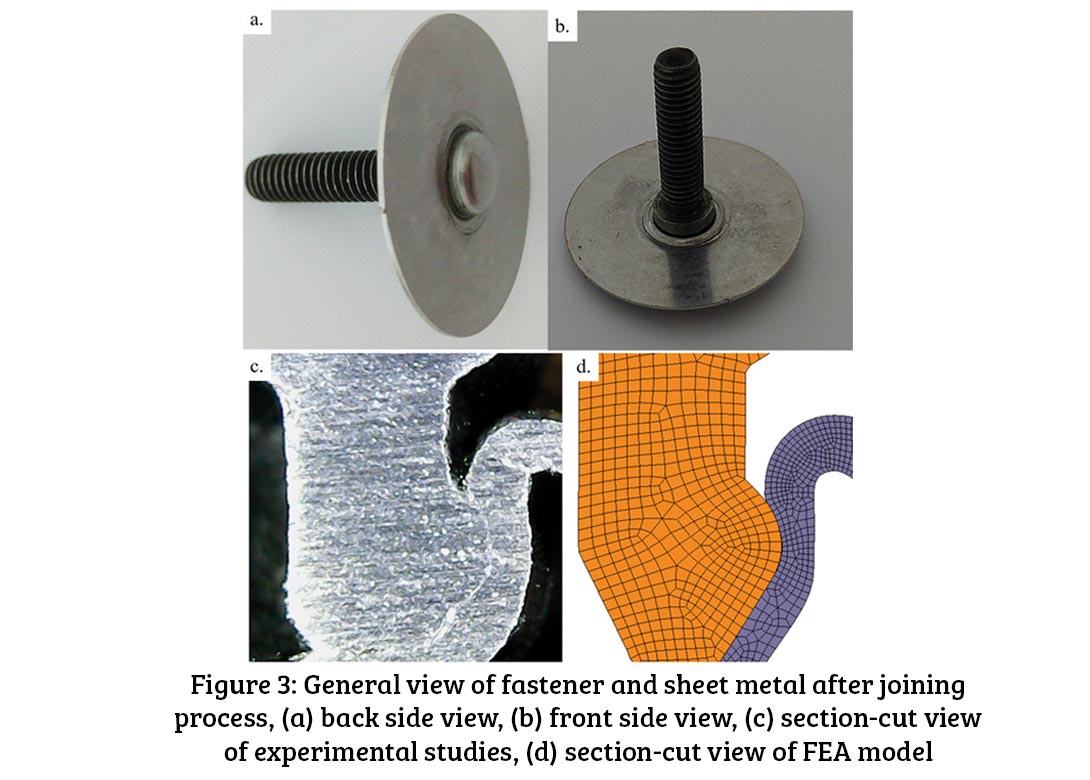

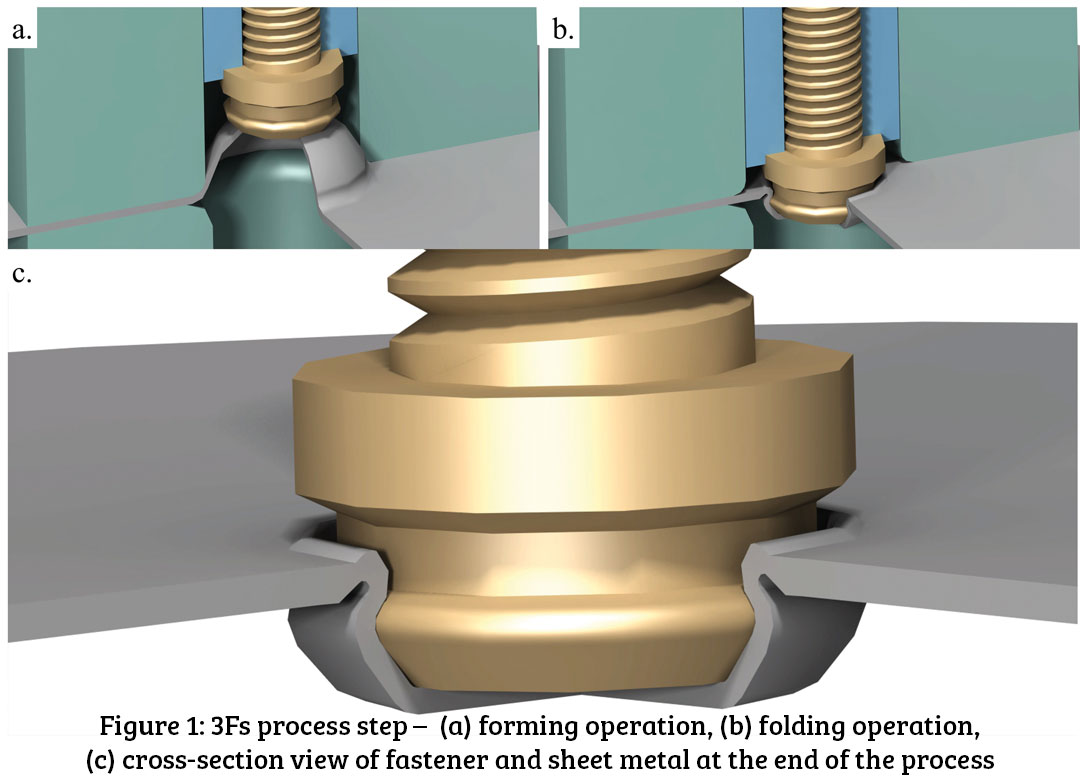

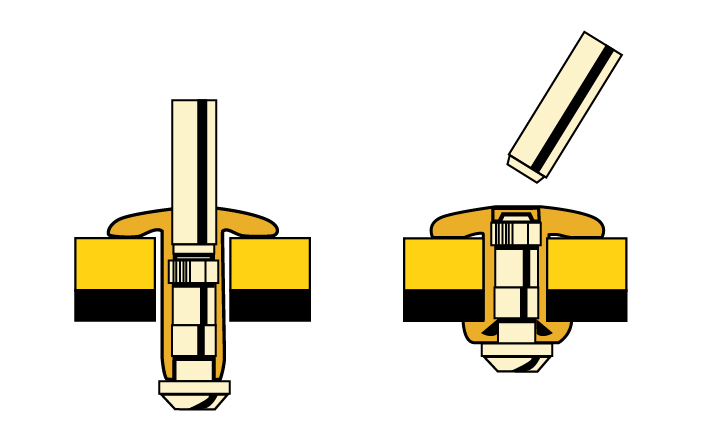

An Innovative Fastening Approach For Thin Sheet Metals And Modelling By Finite Element Method Fastener Fixing Technology

2

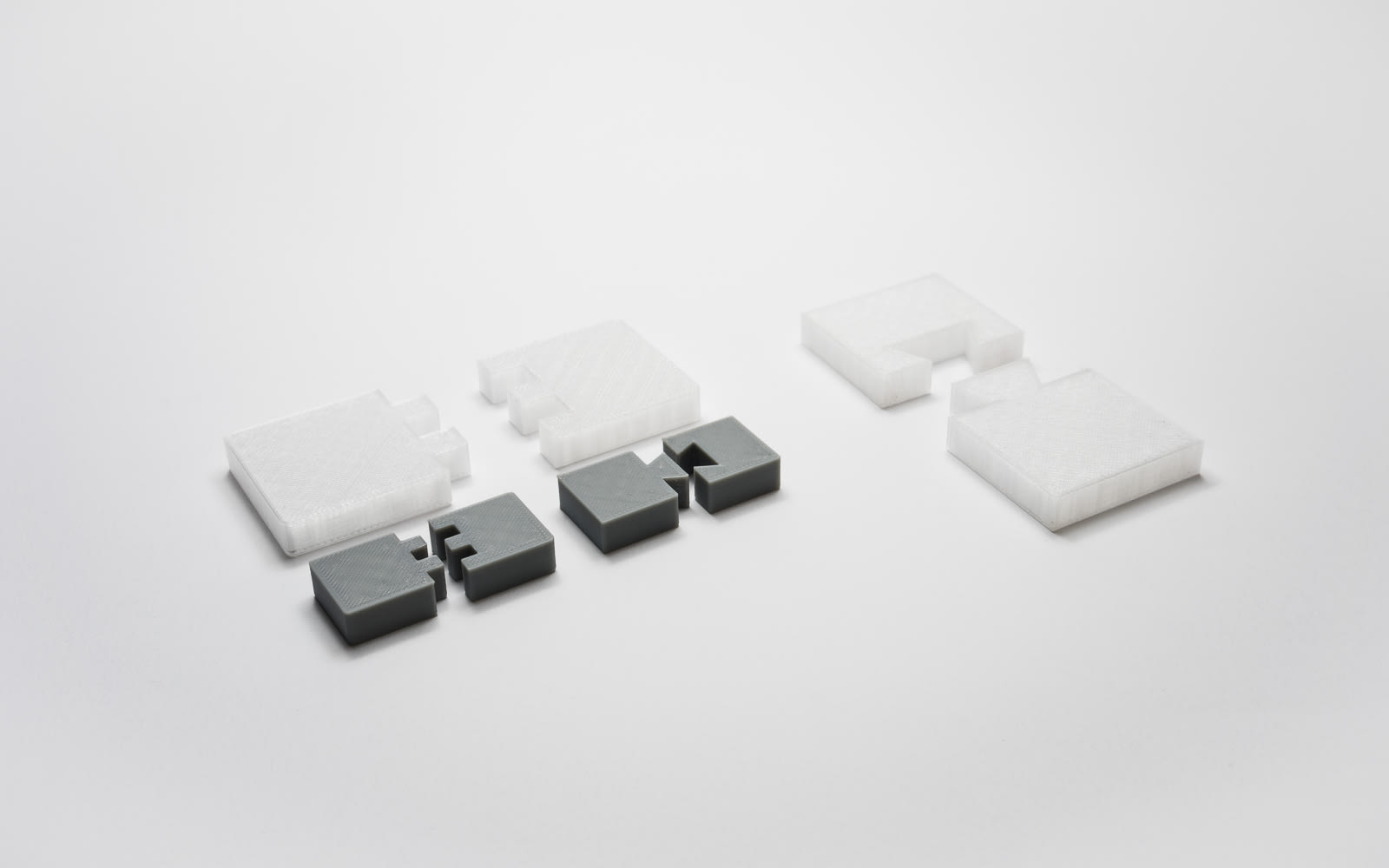

How To Design Interlocking Joints For Fastening 3d Printed Parts 3d Hubs

Following Dfm Guidelines For Working With Sheet Metal Machine Design

Electronic Enclosure Design 101 Protocase Blog

Products Installed By Riveting Choosing The Right Fastener Youtube

Pin On The Use Of Light

Methods For Fastening Sheet Metal Without Fasteners Machine Design

A List Of Common Sheet Metal Fabrication Techniques

Connective Forms Make Fastening Faster Fabricating And Metalworking

Techniques For Joining Sheet Metal 13 06 03 Assembly Magazine

An Innovative Fastening Approach For Thin Sheet Metals And Modelling By Finite Element Method Fastener Fixing Magazine

Types Of Fasteners Nuts Bolts Washers

Q Tbn 3aand9gcqzj F Gzioxpvq7bwqar9dbdbmo7oay6dhwjx5e3wpgtiyya18 Usqp Cau

Clinching Welding Machines And Consumables Www Weldnbraze Com

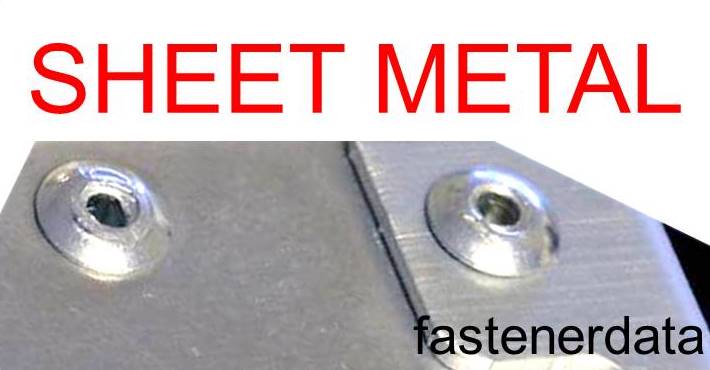

Fastenerdata Fastenerdata Home Fastener Specifications

Sheet Metal Fasteners Ppt Download

Techniques For Joining Sheet Metal 13 06 03 Assembly Magazine

Fasteners Hold A Firm Fix In Thin Sheet Metal

The Power Of Sheet Metal Design

Get A Grip On The Nuts And Bolts Of Holding Your Project Together With This Guide On Fasteners Make

How To Assemble 3d Printed Parts With Threaded Fasteners 3d Hubs

Comparison Of Different Fastening Methods Download Scientific Diagram

The Power Of Sheet Metal Design

Cost Saving Design 5 Sheet Metal Production Techniques St Anns Sheet Metal

Selecting The Best Adhesive For Metal To Metal Bonding Engineering Com

Pem Spotfast Puts Sheet Fastening In A Nutshell Kvt Fastening Austria

Mechanciatech Com

Www Smacna Org Docs Default Source Market Sector Architectural Manual Pp Pdf

6 Types Of Sheet Metal Joining Techniques Machinemfg

How To Join Metal Without Welding Vista Industrial Products Inc

Q Tbn 3aand9gcrbcdz Qfqt9nhespj2sedvanjbvcdxstyqm9gn2zcvxzvgfisw Usqp Cau